I recently watched the movie “Charlie and the Chocolate Factory” (from 2005); and it reminded me that I had made a soap inspired by its predecessor, “Willy Wonka and the chocolate factory” last year.

It turns out that the video of the making of that soap was almost completely edited in my iPad. So I decided it was time to publish it and also revisit the experiment I made along with that soap: Comparing a commercial Vanilla stabilizer against a DIY vanilla stabilizer.

A vanilla stabilizer attempts to control the brown discolorations that a fragrance with vanillin will develop in a soap, and frankly, using a stabilizer is the only way I have successfully avoided brown soaps, when using a fragrance that has vanillin.

A lot of soap makers state that stabilizers are only effective for a few months, but the ones I tried have been effective for more than a year, so there is that.

a DIY Vanilla stabilizer

The main problem I see with vanilla stabilizers (for me) is their price! They cost almost as much as a fragrance, which is why the DIY route makes more sense to me.

I have tried my hand at DIY vanilla stabilizers before like in this post. Using sodium thiosulfate mixed with water, and also a solution of sodium thiosulfate, meta bisulfate and water (a recipe by Todd Z. found here)

The issue I experienced was that those vanilla stabilizers did not work as well for me as the one from Natures’s Garden did. Besides, one of them caused a bad smell in the soap when my fragrance had lavender or floral notes. Thankfully, the bad smell (it was like the smell of perm chemicals) did fade for the most part. It was for this soap video.

There was still another ingredient I had not tried before, that was mentioned in the blog post from ultimate hp soap: sodium bisulfate.

I found some sodium bisulfate at the same place where I sometimes buy photography equipment, and decided to try it. I did a Google search to see if it is safe to add it to the soap; and I did see that this ingredient is added to some food products.

Unfortunately, I did not write the ratios I used in the experiment, or if I did, I cannot find them. However, my guess is that I either made a 25% solution (25% sodium bisulfate and 75% water) or a 50/50 solution. I used this solution at the same percentage as the fragrance (1 oz of stabilizer per 1 oz of fragrance because the vanillin content was high (10%).

I have noticed that it also helps to have an antioxidant in the oils. I normally add Rosemary oleoresin to my oils to prevent rancidity (at the very small rate of 0.05% of the weight of all the oils) and EDTA to the soap batter (at the rate of 0.50% of the weight of whole batch, it needs to be diluted in water prior), and I have seen that it helps diminish brown discoloration.

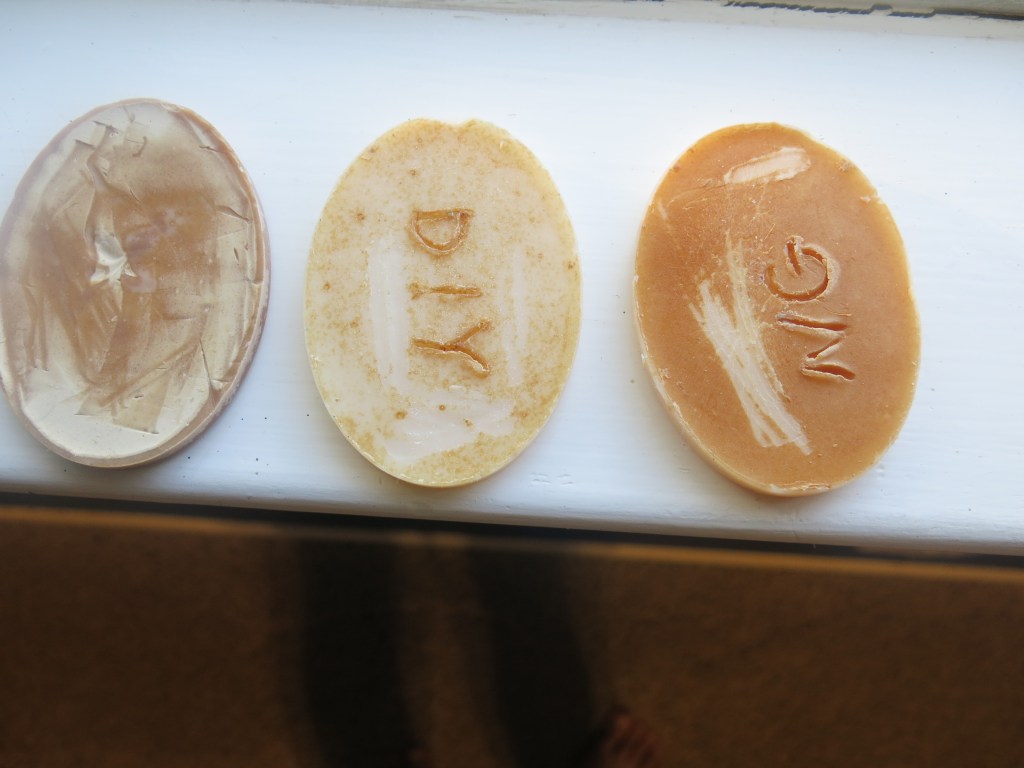

Pictures of the soaps shortly after making them below, in july 2022, the back of the soaps on the left, and the top on the right:

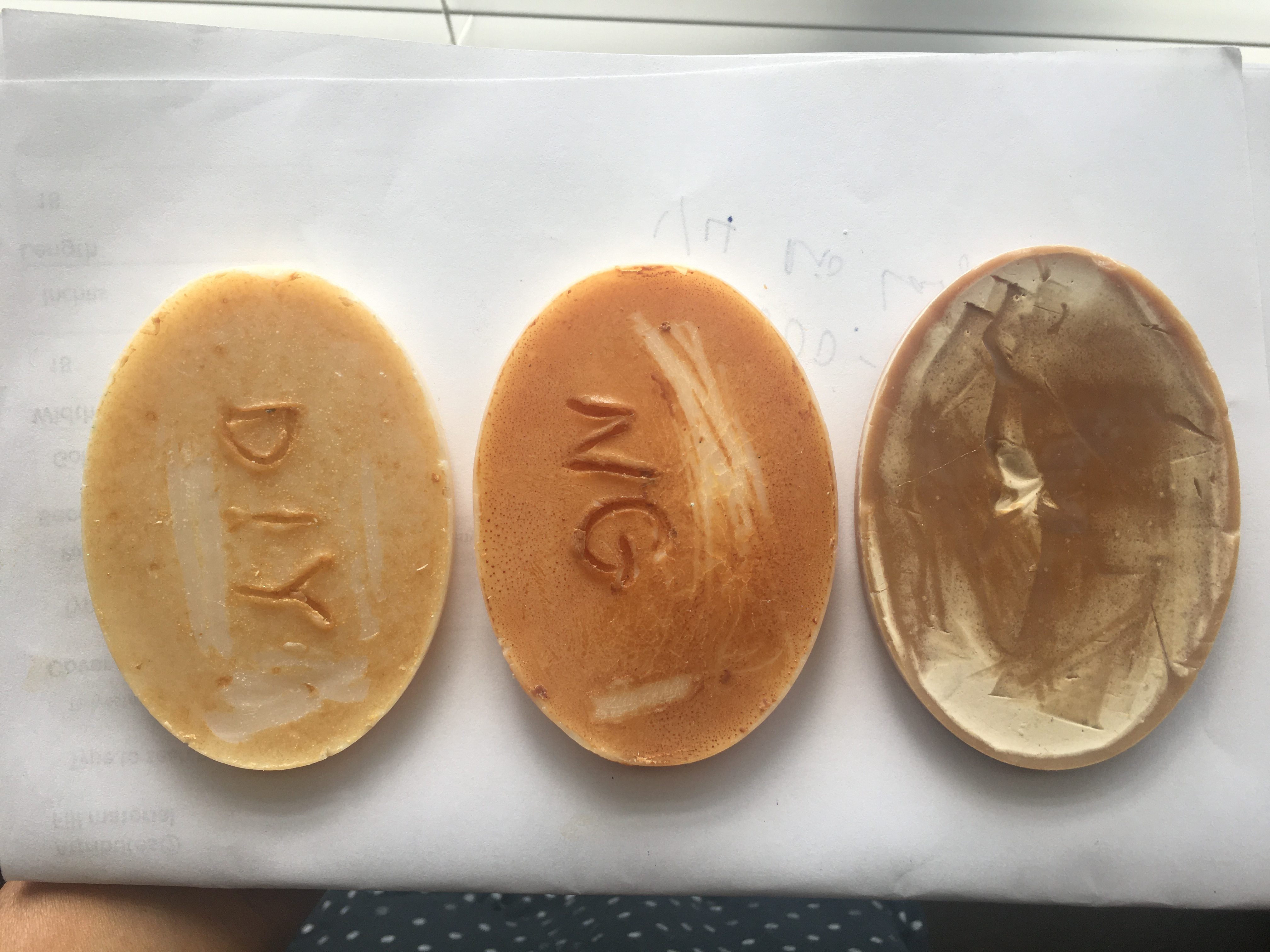

Left soap is without stabilizer, the middle one with my sodium bisulfate mix and the soap on the right with Natures Garden stabilizer. It has been 1 year and four months since I made this soap and I still have the experimental soaps. Here is a picture I took of them yesterday:

As you can see, the DIY vanilla stabilizer performed as well as the Natures’s Garden one. Only the very top usually gets discolored, and I normally shave it off, but left it for the markings. The speckles on the back are not DOS, just random bits of other soaps and flint they picked up but I could easily remove them later.

As far as the scent, it is virtually gone from the darkest soap (the one without stabilizers) but I can still smell vanilla notes (not chocolate though) in the other two.

Here is the recipe and ingredients for the soap and stabilizer. Some of the links below are affiliate links, which means I will get an incentive if you purchase from those links:

Ingredients for DIY Vanilla stabilizer

- Sodium bisulfate, you can buy it here or here.

- Distilled water

- I would make a solution of 25% / 75% to start. 75% being distilled water. For example, 1 oz sodium bisulfate mixed with 3 oz of water.

- Usage rate would be: 50% of fragrance oil if the vanillin content is less than 9%. Or 100% of fragrance oil if vanillin content is higher.

- For example, if the recipe calls for 2 oz of fragrance, and the fragrance has 5% vanillin, I would use 1 oz of the stabilizer solution. If the vanillin content is 15%, I would use 2 oz of stabilizer solution.

You can watch the video of the making here:

https://youtu.be/TcMlc_7Icz4?si=cqGHqmyNgqY6Tbtf

Soap Ingredients

Your can also view it in lyecalc.com here

| Ingredient | Gram(s) | Ounce(s) | Pounds(s) | Oil % |

|---|---|---|---|---|

| Coconut Oil, 76 deg | 220.58 | 7.78 | 0.49 | 24% |

| Ricinus Oil (Castor Oil) | 55.15 | 1.95 | 0.12 | 6% |

| Karite Butter (Shea) | 137.86 | 4.86 | 0.30 | 15% |

| Olive Oil – All Grades | 257.35 | 9.08 | 0.57 | 28% |

| Lard | 248.15 | 8.75 | 0.55 | 27% |

| Ingredient | Gram(s) | Ounce(s) | Pounds(s) | Batch % |

| Lye – NaOH 100% Purity (4% Superfat) | 128.15 | 4.52 | 0.28 | 10.27% |

| Water (40% Lye + 60% Water Solution) | 192.22 | 6.78 | 0.42 | 15.41% |

| Total Oils | 919.09 | 32.42 | 2.03 | 73.68% |

| Soap Weight (Pre-Cook) | 1,247.47 | 44 | 2.75 | 100% |

Custom Additives

| Add with the Fats | ||

|---|---|---|

| Rosemary oleoresin (you will need jewelers scale or small precision scale) | 0.02 oz | 0.46 g |

| Add at trace | ||

| EDTA solution (mixed 50/50 with distilled water) | 0.44 oz | 13 g |

For more information on these additives you can click in the links below, please note above links are affiliate ones

- Rosemary oleresin (My oils already had this added when I masterbatched the oils)

- Tetrasodium EDTA

Colorants:

- Green: 1/4 tsp green mojito mica from WSP + 1/16 tsp of Fluorescent Neon Green from Nurture Soap for 3 oz of soap

- 1/4 tsp hershey’s cocoa powder + 1/4 tsp Bronze Brown Mica for 4 oz of soap, for the river effect

- 1/4 tsp of Bronze Brown Mica + 1/4 hammered copper mica from Wsp for the rest

- Mama clown iridescent white glitter for the top.

If you watch the video, you may wonder why I chose to color the main soap brown and used a vanilla stabilizer; instead of letting the fragrance discolor to brown. The reason is that sometimes when a fragrance discolors, it does not discolor evenly, like in this soap, where it got darker around the embeds, and I wanted an even chocolate color with the soap confetti scraps.

Sample of uneven discoloration with embeds:

Molds:

Embeds

To make the embeds I used soap dough and melt and pour.

- lollipops: you can watch how I made them here.

- gummy bears: you can make them with a mold like this one. I used a mold I made myself but it took a long time. I used clear melt and pour (did not color it). I achieved the different colors by dabbing mica on the back of each bear.

Fragrance:

1.8 oz Chocolate FO from New Direction Aromatics, it smelled like chocolate soufflé to me.

Equipment

Safety Equipment:

- Nitrile gloves

- Facial Shield (I use either a facial shield or the goggles below)

- Safety Goggles

- Respirator (I use this when mixing the lye, I mix the lye in the window sill, window opened, with a pedestal fan blowing the fumes away, better yet, freeze your distilled water prior) I also try to wear long sleeves, pants and closed shoes. In my personal experience, most of my near misses (when I feel my skin itching or a slight burning sensation), or when I come contact with the soap batter, have happened when I am wiping down the containers, when I am almost done.

Process

- Firs, it is a good idea to mixed the micas with olive oil or any clear oil, and measure the fragrances. I use Long and skinny spatulas to do this.

- I also chopped some leftover soap scraps for confetti effect.

- To make the soap, I normally heat up some of my masterbatched oils, weigh what I need and set it apart.

- Then I measure the masterbatched lye needed. However, if you do not masterbatch the oils or lye, I detail it below:

- In a well ventilated area (outside or by a window), add the lye gradually to the distilled water. Do not breathe the fumes. You can freeze half of the water ahead to avoid fumes, and weigh the ice cubes. You need to wear your safety gear. Lye burns! You can prepare this several hours ahead, or even days ahead, keep it properly covered. (If making it the same day, loosely cover it to allow it to cool down. Once at room temperature, use an airtight lid).

- While you wait for the lye water to cool down, you can weigh and melt your oils. Weigh your fragrance oil or essential oils into a glass container or ceramic container (fragrance oils can dissolve thin plastics).

- When your oils and lye solution are at or below 105°F (37.77°C), put on your PPE (Personal protective equipment) again, and add your lye solution to the oils slowly, to avoid splatters pour it on the blender shaft. If your lye solution is cooler than this, is ok. As long as it not near freezing. (Room temperature is fine). If your oils go under 95° F, warm them up to lightly above 100° F

- Stir with the blender on Off position initially, then blend for 5-7 second periods, alternating with stirring for 10 seconds or longer, until it is emulsified. This takes about 30-50 seconds with this recipe. When a recipe reaches emulsion, everything has a uniform, lighter color than before, you do not see the darker oil swirls when blending.

- Separate 4 oz of soap for the grass effect, and color it with the green mica

- Separate 3 oz for the chocolate cascade effect, and color it with the cocoa powder and dark bronze mica

- Color the remaining brown with the dark bronze mica

- Add the fragrance to the soap and stir for about 30 seconds. Add the vanilla stabilizer as well. If the fragrance does not accelerate, blend some more to bring soap batter to light trace. Add the confetti scraps, if using.

- Pour into mold

- Once the soap is somewhat set, with a spatula make an indentation for the grass like shown in the video, and pour the green soap there.

- Add the wall embeds, then pour the chocolate waterfall effect carefully with the reserved soaps.

- then add candy embeds carefully

- Cover with plastic to avoid soda ash (I use Press and seal) I try to promote gel phase by putting a heating pad on the floor, putting a box on top, and covering it with a blanket. I leave the heating pad on for 5 hours or so, on High.

- Wait 48 -72 hours hours to remove, the longer the better to avoid soda ash.

- Let the soap cure for at least 4 weeks in an open area protected from direct sunlight before using. (not touching any metal)

Some concepts explained:

*SUPERFAT:

By now you probably know that lye (sodium hydroxide) converts oils into soap, through a process called saponification. And you probably also know that there are specific amounts needed of each for this to happen. Because each soap has a different SAPonification value, different amounts of lye are needed for each oil.

Superfatting sounds like something I like to do to myself when I keep eating after I feel full. But in the soap world, many will know it is when you either add more oils or less lye than it is required. Let’s say, hypothetically, that you need 3 oz of lye to convert 16 oz of manacao oil (totally made up oil) into soap. If you only use 2.5 oz of lye instead of 3, that means that a percentage of the manaco oil will not become soap, but will remain an oil. And this is desirable as that extra oil will cause the soap to become more gentle on your skin, by reducing its cleansing ability slightly. But if you use 4 oz of lye instead of 3, that means all 16 oz of manacao oil will become soap, and not only that, there will be extra lye floating around. That extra lye will be looking for more oil to convert to soap, that oil could be the natural skin oils, which means this soap can burn or irritate the skin.

Usually superfat of at least 3% is recommended as oils properties may change from crop to crop. But even if you had a 0% superfat soap, it would still be gentle as handmade soap creates glycerin, which is a skin humectant. (From most commercially produced soap, glycerin is removed to be sold separately).

*LYE CONCENTRATION / WATER DISCOUNT:

Most soap calculators will give you the amount of water needed to mix the lye with, based on traditional cooking methods of making soap, what we now know as hot process. This is a big percentage of water (38% of the oils) because a lot of it would evaporate through the cooking process. However, for cold process soap this is usually too much water, which can lead to a lot of soda ash or a lot of shrinkage during the cure.

This blogpost explains it better (from modern soapmaking).

2 thoughts on “How to avoid brown soap discoloration and making a Chocolate Factory Soap”