“If you hear a voice within you say “you cannot paint,” then by all means paint and that voice will be silenced. ”

– Vincent Van Gogh

Lately, I have been contemplating the idea of making dividers for scenic soaps, rather than using the sculpted layers technique (soap scrapers). I have come to realize that I lack the patience needed to do the sculpted layers technique, even when I have tried it with an accelerating fragrance. With a divider, It seems it would be faster than waiting for layers to set up enough to be scraped, as everything would be poured continuously. It occurred to me that the starry night Painting might be a good test for this idea. If it works, it would give most people the opportunity to make a painting style soap regardless of their painting abilities, it would sort of be like a painting by numbers tool. And I could also redeem myself from my previous attempt.

The main challenge is making the divider, but with a 3-d printer it should be a lot easier. I will document the planning and making of this soap here. Sort of like a soap diary.

2/7/21. It’s super bowl Sunday but since I am not into football it is Sunday as usual for me. I decided I could “tackle” the design of the divider today (pun intended). I printed a black and white version of the starry night, and I marked with a sharpie the main sections for the divider. Then, I went over the lines that had bled through the paper on the back. I took a picture of it that I could modify in photoshop. It looks like this:

Since this is happening on the back of the paper, it is reversed. I can flip this easily later in the software. I did several adjustments and once I converted it to a 3-D printing file, I realized it would take too long to print: 9 hours! That won’t do, so I made the lines thinner by drawing them in the computer. It says it will take 5 hours now, that’s more manageable. I had to simplify the painting so that it would work at such small scale.

2/7/21

I will attempt to 3-d print the divider today. I say attempt because I will use ABS filament, and that is a tricky filament to print with. However, it should be strong and better able to handle warmer temperatures than PLA filament.

I won’t be able to attempt the soap for several days though, as I need to make a shampoo bar, a fire themed soap, and an orange hot process soap first. I tend to get soap making ideas, get most of the things needed for the design to be made, and then abandon the project when a new idea comes along. So I have made it a rule that I won’t try a new soap idea until I finish a project that is halfway through. Besides, the mold in which I plan to use this divider, will probably take 3 weeks to arrive.

I have made the divider, it required a bit of cleaning, but it seems it could work. Now I must wait for the mold, which gives me plenty of time to do the other projects and I also need to masterbatch the oils.

2/19/21

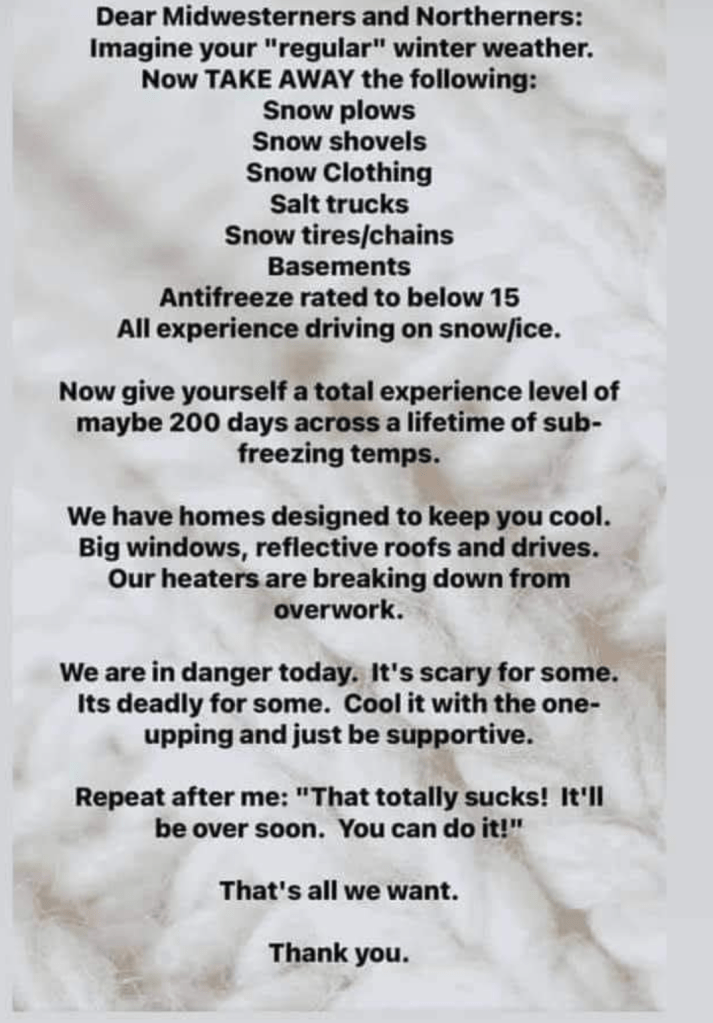

Have had a rough week. Record breaking temperatures for Texas. Two winter storms in a week and loss of power and water for millions. I have lived in Texas for 20 years. I can count on one hand the number of times it has snowed in those 20 years. (Suddenly I feel very old). Anyway, all the times prior, when it snowed, it kind of followed the same pattern: The news would announce it, people would freak out initially, and then start looking forward to making a one foot tall snowman with their kids. School would be cancelled and local government would encourage everyone to stay home. Then the snow would fall, a very light white dusting on top of the grass would appear overnight, and people would take pictures and post them in social media. Then by the afternoon the sun would melt the snow and life went back to normal.

This time it was different, the snow came to stay for longer than a couple of days, it was thicker too. If you live someplace where it regularly snow, you may mock the reaction of Southerners to it. This may explain it better than I could:

Several people have died either from hypothermia or from exhaust fumes from coal or generators, it saddens me so much. We were among the few ones who did not lose power for a long period of time, just 11 hours. (In those 11 hours we kept warm with sweaters and a gas fireplace. A lot of people did not have that option, my mom and sisters for example. They lost both water and electricity, and drove a treacherous way, roads covered with ice and snow to our house to spend the night. Some of the fatalities were on the roads because of that as well.

Anyway, in soap related news, Wholesale Supplies emailed me that my order has shipped, 13 days after placing it (which is usually how long it takes normally) during which they had sales and I added extra stuff to the same order. I did the shampoo bars, found a recipe that was fairly easy and for which I had all the ingredients, except one, but did have a suggested substitute.

If I can manage to make the hot process soap I had planned and masterbatch the oils, I could theoretically make the soap as soon as that order comes. But knowing me, I will probably leave the box to sit for a couple of days, then film the unboxing, so who knows.

2/24

The order arrived! If I can find coconut oil, I should be able to do the soap this weekend. Finding the big jars (102 oz) of coconut oil might be tricky. I prefer to purchase coconut oil locally from a Big Lots store, price wise, it is what makes the most sense to me. However, after searching online which store had it, I drove there but it was nowhere to be seen, I asked the cashier and she told me they only had the small ones. Aarrrg! Drove there for nothing. So what I did instead is that I placed an online order for curbside pick up from another location that supposedly also has it in stock.

2/25

I just got an email that it is ready for pick up. yay! So hopefully I can get it today, prepare the masterbatch, and make the soap this weekend.

2/27/21

I opened the WSP order and tested the divider in the mold. It is slightly snug. I am able to remove it if I pull up simultaneously with both hands with some resistance. However, I am worried that once I am wearing soapmaking-oil touched gloves this would be a lot more difficult. I may need to keep some pliers handy but last time I broke a divider with that. I used a stronger filament this time, so maybe that won’t happen. But I also did a low infill % to speed printing…It seems that molds in general, are a tiny bit smaller at the bottom than the top, this is to make the molded item easier to remove, something called “draft” . Which could explain why the divider is snug mostly at the bottom portion.

Last night I made the village and the stars and the moon with leftover soap. I cannot properly call it soap dough because most of it had hardened due in part to a lack of proper storage. So instead of using an extruder, which would have made it easy, I had to cut and manually shape the village and the stars. Last time I used an extruder and it was faster. I may dust the houses later with black mica for an outline effect.

2/28

The weekend has come and gone and I did not make the soap yet. There were several details I had forgotten about, but I think I am ready now. I chopped several soap shavings to hopefully get the effect of paint strokes and if not, at least different shades of blue in each section. I calculated how much of each color I should prepare, roughly also estimated the amounts of colorants. It seems I am procrastinating in making the soap now, I wonder why. I can tell I am procrastinating because I find myself doing other stuff, such as reorganizing all the soap dough and soap scraps. I threw away a lot of it, mostly what had developed DOS. I also reorganized my filming table set up, changed the lighting and cleaned up the area, it has been over a month since my last soap making session.

3/1

I just did the soap! And while still fresh in my mind, here are some notes to my future self:

- Forget about adding soap scraps in the future. As tiny as they were, they were getting stuck in the tiny crevices and decreasing the flow of the blue sections. Rather, do what you had planned initially to do: either oil mica swirls or do a mini in the pot swirls for the blues.

Add more water to recipe so that instead of 40% lye to water concentration, it would be either 34 or 36%This is crossed with a line because:- it turns out I was using 28% lye to water concentration because I was using the same lye water intended for a hot process soap (the orange soap), so maybe I will try 40% next time after all.

- Start pouring after mixing colors, even if you think the soap batter is too thin; do not wait for the greens to come to trace, leakage at the bottom will happen regardless.

- Possibly modify the tree to make the top part wider, the narrow tip is not reading well in final product

- Very important: have a water bowl to rinse the divider between uses.

- Reduce the amount of colorants for the light blue portion.

So here is what happened: I brought the soap to emulsion, mixed all the colors but the blue, because the blue had some ultra marine pigment, which tends to speed trace and thicken up the soap batter. But I had to wait because the green portions seemed too thin. I probably waited less than 5 minutes. Then I mixed the blues and started pouring. The first soap poured nice, but by the third and fourth soap, the soap batter was too thick, and by the time of adding the house embeds, the soaps were considerably thicker. The house embeds are too long too, and the stars, so I will need to trim them after unmolding. Overall, it was a learning experience. not as bad as it could have been, but not as fantastic as I could have imagined. Here is a picture:

My blues were spilling over as I rushed to pour before it got too thick. The fragrance I used has behaved better in the past, but it was a different recipe, and more water.

I might try this again since this was my first attempt. We shall see.

3/13/21

I attempted stamping the soaps yesterday, (on the back) and since it has been several days from unmolding, the process caused cracks and also one of the house embeds came apart slightly.

The bars developed a lot of soda ash because of the high water content in this recipe. I used the same lye water solution I had prepared for a hot process soap. I trieed to remove the soda ash as best as I could but planing them definitely helped:

Overall I was happy with how the idea worked. However I did not like the colors as much. So I attempted 3-D printing a new divider, and I tried another small batch with it, this time I used a 40% lye to water concentration (my standard lye master batch ) and also did the following changes:

- Stacked the house embeds together, so that they will be easier to place

- I adhered most of the embeds to the mold before pouring, using melt and pour as the “glue “

- I used different micas for the colors and different amounts.

- I put the soap batter in condiment bottles for easier pouring

- I rinsed the divider between uses

- The following day I attempted to force gel phase by putting a heating pad underneath for two hours on high, (not sure if it will work since they are cavity molds and my low water amount means reaching gel requires a high temperature).

- I added glitter on top of three of the bars.

- Used a different fragrance that is better suited for intricate swirls

What I can tell from this attempt, is that there is a better definition of the divider sections in the third and fourth bars. Probably because by then the soap batter had reached trace. I also made too much light green soap, and I lacked enough of the uncolored or light blue portion.

And the final pictures:

Video:

Supplies used:

Equipment

Mold

Rectangle cavity mold from Crafter’s choice

Fragrance:

Fragrance

0.85 oz of pink grapefruit fragrance

0.30 oz of Honey formulator fragrance

Colorants

- For tree: 1/2 tsp Savage Green Mica from Nurture Soap, dispersed into 4 oz o soap batter

- For the ground: 1/2 tsp of Alpine Green Mica dispersed in 7 oz of soap batter

- Dark blue: 1 tsp Kashmir Mica (Blue) from Nurture Soap + 1/4 tsp Midnight blue mica for 7 oz of soap

- Light blue: 1/4 tsp Starry Night enviroglitter

- Whatever soap is left will be uncolored – off white.

- Super Sparkles Enviroglitter for a mica swirl and decoration on top.

- Starry Night Enviroglitter for a mica swirl on top

Embeds

- Soap dough to make the houses, moon, stars, (yellow, white, brown, blue, black, etc.)

- Clay extruder (with discs in the shape of a triangle for the house roofs, square for the houses)

My affiliate links:

Several of the links above are affiliate links, as the ones below. If you buy from them, it will not cost you any more, and I would get a tiny commission on it.

Recipe Totals

Note: I am using a lye blend that includes Koh (Potassium hydroxide), mainly because I bought some for a project, did the project, now I have a lot leftover and want to use it up. Also because I have read that it helps increase bubbles, and my husband loves a bubbly soap. You can enter the ingredients in a lye calculator and modify the recipe, to get the correct amount for just Naoh.

Recipe Oils, Fats and Waxes

| Oil | % | Ounces | Grams |

|---|---|---|---|

| Olive Oil | 30 | 5.4 | 153.09 |

| Tallow Beef | 30 | 5.4 | 153.09 |

| Coconut Oil, 76 deg | 25 | 4.5 | 127.57 |

| Castor Oil | 8 | 1.44 | 40.82 |

| Shea Butter | 7 | 1.26 | 35.72 |

| Total | 100 | 18 | 510.29 |

Recipe Totals

| Liquid Required | 3.91 oz | 110.91 g |

| NaOH Weight | 2.41 oz | 68.34 g |

| KOH Weight | 0.2 oz | 5.61 g at 90% Purity |

| Lye Weight | 2.61 oz | 73.94 g |

| Oil Weight | 18 oz | 510.29 g |

| Fragrance Oil Weight | 1.13 oz | 31.89 g |

| Superfat | 5% | |

| Total Batch Weight | 25.9 oz | 734.31 g |

| Lye Concentration | 40% |

Custom Additives

| Add with the Fats | |

|---|---|

| Rosemary oleoresin | 0.01 ounce |

| Add at trace | |

| EDTA mixed with water (50/50 Solution) | 0.23 ounce |

For more information on these additives you can click in the links below, please note above links are affiliate ones

- Rosemary oleresin (My oils already had this added when I masterbatched the oils)

NOTE: This project is intended for intermediate soap makers, if you are a beginner I would suggest you read this post before.

NOTE 2: I have a big water discount above, to avoid soda ash since it is difficult to avoid it in small cavity molds and in my area (where humidity is high). I forced gel with a heating pad (for 7 hours on high), and by covering the mold with Press and seal and a blanket.

For my previous attempt, I used these colorants:

| COLOR | Micas | Dispersed into: |

| Light yellow | 1/8 tsp of yellow mica | 1.40 oz of soap |

| Strong blue | 1/4 tsp Blue ultramarine pigment & 1/4 tsp of Midnight blue mica | 7.85 oz of soap |

| Green for the ground | 1/2 tsp Savage Green | 7 oz of soap |

| Light blue | 1/8 tsp of midnight blue mica and 1/16 Ultramarine pigment | 7.50 oz of soap |

| Green for tree | 1/4 tsp Savage green and 1/8 tsp of black pearl mica | 4.2 oz of soap |